With know-how and competence in every phase

Our core business is engineering for the paper industry in brownfield or greenfield projects. Our main focus is on the rebuild and optimization of existing plants. We are market leaders in the planning and implementation of wastewater treatment plants. Both require a lot of expertise and the know-how of various specialists. M Consult brings the experience of more than 1,200 implementation projects and has a team that covers all areas of competence.

Our knowledge spectrum includes paper, electrical, measurement and control technology and environmental engineering. Your advantage: With M Consult you have a partner at your side who masters the entire process engineering of your core processes. In addition, we have a network of planners with whom the ancillary trades can be covered. Thus, we offer you all engineering services from one source.

The main engineering stages at a glance

As soon as you have decided on a particular plant concept or optimization project – for example, on the basis of a feasibility study prepared by us – we start the first stage of implementation: pre-engineering.

Pre engineering

In the course of the technical pre-engineering, the rough dimensioning of the central technical plant components as well as the material flows is carried out and layout variants are designed. In order to be able to provide you with a maximum of planning reliability already in this early phase, we use, for example, state-of-the-art simulation software. In addition, we provide you with initial time and cost estimates for the implementation of your project. Proper pre-engineering mentally anticipates project contingencies – before investment decisions are made. This avoids costly changes later in the project and all planning trades have binding guidelines for the following basic engineering phase. This saves time.

Basic engineering

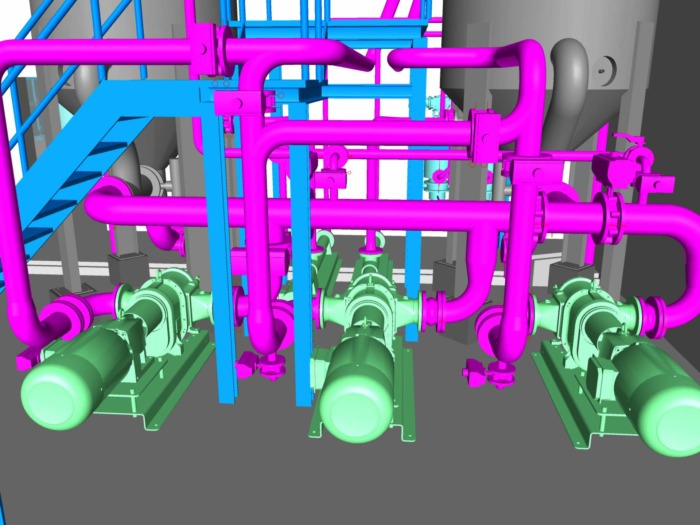

The next step is basic engineering, i.e. design and process planning. In this process, we balance the process, we lay out the main technical components of your new plant, draw a piping and instrument flow diagram (P&I diagram), refine the layout, visualize central construction and plant components – for example in guide drawings. Further results are, for example, a well-founded estimate of the implementation costs as well as the tender documents.

Detail engineering

We use the final engineering phase for the detailed design and technical description of all plant components and implementation measures. The 3D model of the plant and the detailed layout is enriched with a database, so that all technical information relevant for the execution is included. The refined P&ID scheme is provided with detailed information on the process sequence, such as control loops, valves, vessels, main pump data and other aggregates. These are also available in a database. This allows us to provide your team or the contractors directly with all the necessary lists and construction-relevant information.